What is offset printing ?

Offset printing is a printing technique whereby ink is spread on a metal plate with etched images, then transferred to an intermediary surface such as a rubber blanket, and finally applied to paper by pressing the paper against the intermediary surface. We and most print shops use offset printing to produce large volumes of high-quality documents, such as leaflets, brochures, business cards and so on. Although the equipment and set-up costs are relatively high, the actual printing process is relatively inexpensive.

Offset printing is one of the most common flat printing techniques, wherein ink is transferred from a plate to a rubber blanket, then back to the printing surface. Like most types of printing, offset printing is a mix of art and science. Although the process is very technical (the science part), the press operator also carries a lot of weight in achieving the desired outcome of the printed piece.

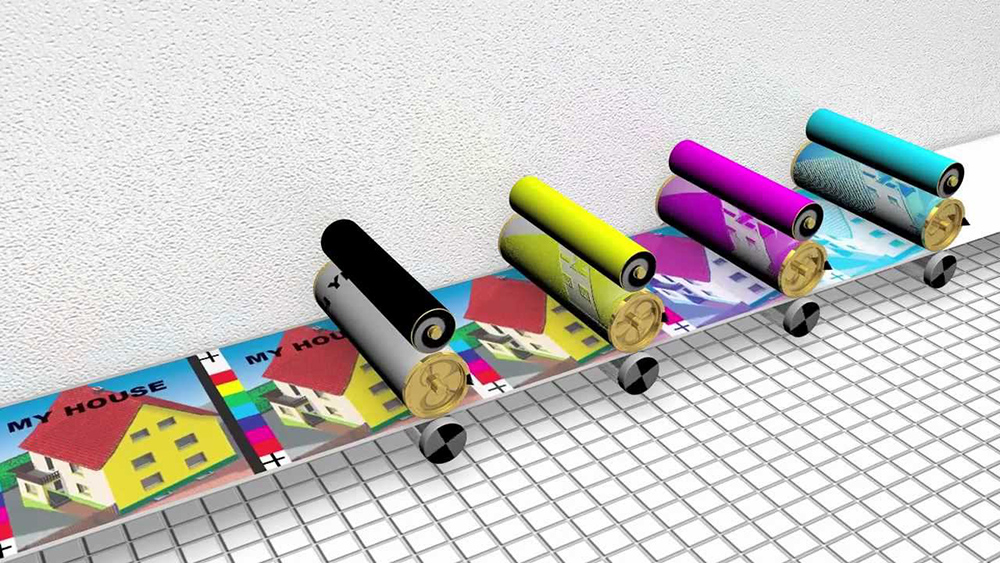

Before offset printing, a printing plate is created for each printing ink, so there is a total of 4 plates for the 4 colours C-M-Y-K. The image surfaces, which will later be filled with ink during the printing process or remain free, are placed on one level on the printing plate. Here the physical basis is the different surface structure, which comes about due to the exposure of the plates. This means that colour only remains where this is intended. Therefore there is a printing plate for each colour, as only the motif is exposed on the plate which is to be printed in the respective colour. The plates are then inserted into the respective printing unit (matching the colour) in the offset printing machine. The printed sheet passes through all 4 units after each other which results in all colours being printed on top of each other.

The most important part of the offset printing process is the very beginning. It is important to ensure that you have very well prepared files. One of the biggest mistakes we see is a simple one, files must be converted from RGB to CMYK in order to print offset. This conversion will change the look of your piece, sometimes marginally, sometimes dramatically. Many designers are unsure how to prepare their files for an offset print job and can end up running into unplanned prepress costs to correct them. If your a graphic designer and need help and advice with how to prepare your files for offset printing then please contact us, we offer free and friendly advice.

History of offset printing

The offset press was accidentally invented by Ira Rubel, a papermill owner in New Jersey, at the beginning of the 20th century. He used a lithographic stone press to print bank deposit slips and his press operators would occasionally miss a sheet, causing the press to print an image on the rubber surface of the impression roller. Consequently the next page fed to the press would get printed on both sides: on one side by the image from the lithographic stone and on the other side by the ink from the rubber blanket of the impression roller. Rubel noticed that the image transferred by the blanket was clearer and sharper than the one transferred by the stone plate. He joined forces with another printer to build a press that would always transfer the image first to a rubber blanket and then have it ‘offset’ on a sheet of paper. Their first offset press was soon followed by others and nowadays this is the most commonly used industrial printing technique.